Boiler Repair: Troubleshooting Signs, Costs, and When to Call a Professional

Outline:

– Introduction: why boiler repair matters for safety, comfort, and efficiency

– Troubleshooting signs you shouldn’t ignore, with quick, safe checks

– Cost breakdown: parts, labor, timing, and hidden variables

– DIY vs professional: what’s reasonable at home, what requires certification

– Preventive maintenance and repair vs replace: making an informed decision

Why Boiler Repair Matters: Safety, Comfort, and Efficiency

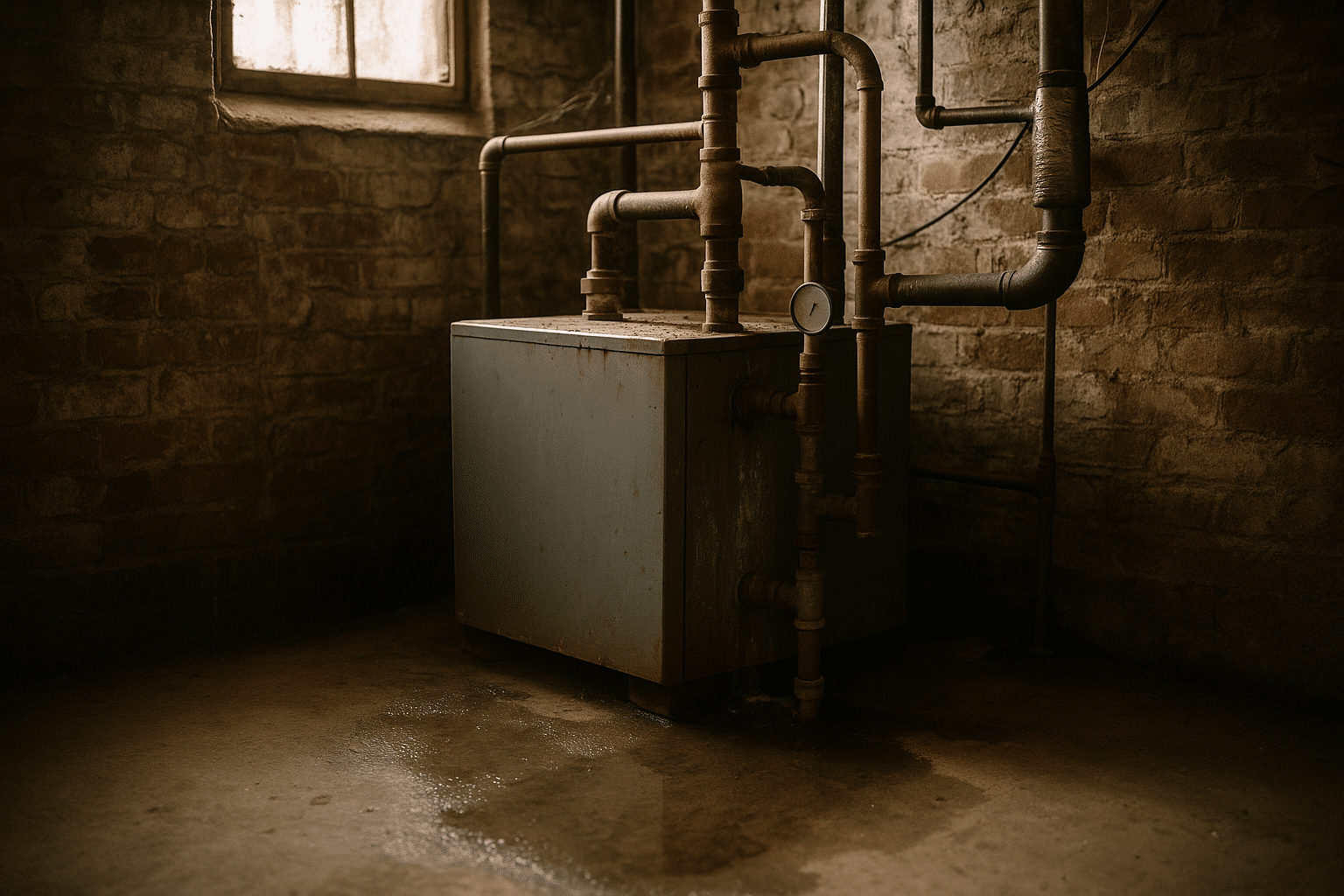

Your boiler sits quietly at the edge of your home’s routine, yet it anchors comfort, safety, and operating costs. When performance slips, the symptoms often start small—an extra minute to reach temperature, a rare clang, a drip that dries before you notice. Left alone, those hints can morph into a no-heat emergency on the coldest week and, worse, create safety hazards. Gas and oil appliances must manage combustion cleanly; water and steam systems must contain pressure reliably. A well-maintained boiler is not only quieter and more consistent, but also less likely to produce carbon monoxide, over-pressurize, or waste fuel.

Safety is the first reason to take repair seriously. Incomplete combustion can elevate carbon monoxide, which is odorless and dangerous. A yellow, flickering flame or persistent soot indicates trouble. Over-pressurization can force relief valves to vent hot water or steam; under-pressurization strains pumps and can introduce air, accelerating corrosion. Electrical faults risk nuisance trips or, in a worst case, arcing. Meanwhile, unnoticed leaks cause scale, which acts like a blanket on heat exchangers; even a thin layer of mineral deposits can meaningfully reduce heat transfer, raising run times and fuel use.

Reliability is the second reason. A boiler under stress short-cycles, starting and stopping more often, which is hard on relays, pumps, and ignition components. That pattern often shows up in winter when demand spikes. Every abrupt stop and start is like city driving for your heating system—wear accumulates faster than you expect.

Efficiency is the third pillar. As parts drift out of calibration, combustion and circulation lag behind what the system was built to deliver. The result shows up on your utility bill. Preventive repairs and timely part replacements can restore proper burn, stable pressure, and balanced flow, trimming fuel waste and extending equipment lifespan. In short, repair isn’t just fixing what’s broken; it’s safeguarding your home, your budget, and your peace of mind when temperatures dip.

Troubleshooting Signs You Shouldn’t Ignore

Boilers weave a story in sounds, temperatures, and gauges long before they fail. Listening to that story can spare you bigger headaches. Start with these high-impact symptoms and what they may mean:

– No heat or intermittent heat: Could stem from thermostat issues, tripped breakers, a failed ignition component, a closed gas valve, airlocks, or a circulation problem.

– Rapid cycling (short bursts on and off): Often tied to incorrect pressure, a faulty sensor, poor circulation, or a control logic fault.

– Kettling or loud banging: Limescale on the heat exchanger, trapped air, or flow restrictions can create hot spots and boil-like sounds.

– Pressure swings: A failing expansion tank, stuck pressure relief valve, or hidden leak may be involved.

– Yellow or unstable flame on gas units: Indicates incomplete combustion and requires immediate professional attention.

– Soot, smoky smell, or visible fumes (especially oil-fired): Signals combustion trouble and is a safety concern.

– Radiators cold at the top: Usually air in the system, calling for a careful bleed.

– Visible leaks or frequent top-ups: Suggests a system leak or failing auto-fill components that deserve swift diagnosis.

Do a few safe checks before calling for help, especially if heat is partially working. Confirm the thermostat is set to heat and above room temperature. Ensure power to the boiler is on and the circuit breaker hasn’t tripped. Verify the gas shutoff lever is parallel to the pipe (open) if your installation uses a visible valve and you’re qualified to check it visually. Review the pressure gauge when the system is cold; many residential hydronic systems operate around 1.0–1.5 bar (roughly 15–22 psi), though always follow the manufacturer’s rating plate and local codes. If radiators are cool at the top, carefully bleed them with a radiator key and a towel; stop if water discolors or sputters wildly.

When temperatures plunge, check the condensate line on high-efficiency models; outdoor or uninsulated runs can freeze, causing lockouts. If you suspect a frozen line, warm it gently with a towel soaked in hot water and call a pro to address insulation and routing. Replace the battery in your thermostat if it’s battery-powered. Keep combustion air pathways clear—clutter around the boiler can starve flame quality. Crucially, do not open sealed combustion chambers, alter gas or oil delivery components, bypass safeties, or reset lockouts repeatedly. If you ever smell gas or observe soot accumulation, evacuate and contact emergency services and a licensed technician.

Cost Breakdown: Parts, Labor, and Hidden Variables

Boiler repair costs vary with fuel type, complexity, and timing. Understanding likely ranges helps you plan and avoid sticker shock, especially during a cold snap when schedules tighten. While prices differ by market, here are typical ballparks for common items (labor included where indicated, in general U.S. ranges):

– Diagnostic visit: $80–$200 (often credited toward repair).

– Minor sensor or switch replacement: $120–$300.

– Thermocouple or flame sensor: $80–$250.

– Ignition module: $150–$500.

– Circulator pump: $200–$800, depending on size and valves involved.

– Diverter or zone valve: $250–$600.

– Expansion tank: $100–$350.

– Pressure relief valve: $120–$300.

– Gas valve (with calibration): $350–$800.

– Heat exchanger: $1,000–$3,000 (labor-heavy, may prompt a replace-vs-repair decision).

– System flush for heavy scale or sludge: $300–$900, based on system size and condition.

Labor rates commonly span $75–$150 per hour, higher in dense urban areas or remote regions. After-hours or emergency service often carries a premium—1.5× is not unusual on nights, weekends, or holidays. Travel time, parking, and access constraints (tight basements, concealed piping) also influence bills. Fuel type matters: oil-fired systems can require additional nozzle and combustion adjustments; electric units eliminate combustion tuning but may incur higher electrical diagnostic time. Hydronic zoning, radiant floors, or integrated indirect water heaters add complexity, sometimes necessitating extra valves or air separators during repair.

Hidden variables create the widest spread. If the boiler is older and isolation valves are missing, a simple pump change can turn into partial system draining and refilling. Severe corrosion may snap bolts or threads, adding time. Water quality issues—hardness, oxygen intrusion—drive recurring scale or sludge, leading to repeat service unless corrected with treatment and filtration. Permits may be required for gas valve work or major component replacements, and that means inspection fees and scheduling considerations. To tame uncertainty, ask for: a written diagnostic, line-item estimates, warranty terms for parts and labor, and any recommended preventive steps that would reduce future callouts.

DIY vs Professional: What You Can Safely Do

Some boiler tasks are fair game for a careful homeowner; others are squarely in licensed territory for good reason. The rule of thumb is simple: anything touching combustion, pressurized gas, fuel oil delivery, sealed chambers, or high-voltage wiring belongs to a professional with the right certification and test equipment.

Reasonable homeowner actions include:

– Checking the thermostat settings and replacing its batteries if applicable.

– Verifying power and resetting the boiler once after a brief outage (avoid repeated resets).

– Bleeding radiators slowly to remove air, monitoring pressure and topping up only if your system’s manual explicitly permits.

– Keeping vents, louvers, and combustion air pathways free of dust and storage boxes.

– Inspecting for visible leaks on accessible piping and catching drips with a pan while awaiting service.

– Insulating exposed, unheated-space pipes to reduce heat loss and freezing risk.

– Testing carbon monoxide and smoke detectors monthly and replacing batteries annually.

– Vacuuming dust around (not inside) the boiler cabinet to maintain airflow.

Tasks to leave to a certified technician:

– Combustion analysis and adjustment, including gas valve calibration and burner tuning.

– Oil nozzle and electrode alignment, draft regulation, and flue adjustments.

– Opening sealed combustion chambers or modifying safety interlocks.

– Replacing heat exchangers, control boards, and high-voltage wiring.

– Pressurized gas or oil line work, pressure testing, and leak detection with calibrated instruments.

– System-wide power flushing, chemical treatment, and inhibitor dosing beyond simple top-ups.

Beyond safety, professional service protects warranties and ensures compliance with local codes and insurance requirements. Many jurisdictions demand that fuel-burning appliances be serviced by certified personnel. A pro will document combustion numbers, verify clearances, test safeties, and spot early signs of failure you might miss—like a weeping relief valve that points to an expansion tank on the edge, or a slightly lazy ignition that heralds a failing module. If you’re unsure where a task falls, default to caution; the cost of a callout is far lower than the consequences of a combustion or pressure incident.

Preventive Maintenance and Repair vs Replace: Making the Call

Preventive maintenance stretches equipment life, tames energy costs, and uncovers problems when they’re inexpensive to correct. An annual service for fuel-burning units is widely recommended: inspectors clean burners or nozzles, verify flame quality, check gaskets, test safety circuits, and confirm venting integrity. For hydronic systems, purging trapped air, checking expansion tank charge, and inspecting pumps and valves reduce the odds of winter surprises. Water chemistry matters: in hard-water areas, scale accumulates faster, so treatment or periodic flushing pays off. A thin veil of mineral deposits may sound harmless, but its insulating effect forces longer burner run times and hastens wear.

A practical checklist for the year:

– Schedule a full tune-up before the heating season.

– Test carbon monoxide and smoke alarms.

– Inspect visible piping and joints for staining or verdigris; tiny leaks often start as discoloration.

– Exercise shutoff valves gently to prevent seizing.

– Confirm pressure cold and warm; note changes in a log.

– Keep the area around the boiler clear by a couple of feet for airflow and service access.

– Insulate long pipe runs in unconditioned spaces to cut losses and reduce condensation.

When deciding to repair or replace, weigh age, condition, and cost. Many modern boilers serve 12–15 years with regular care; cast-iron units can last longer when water quality is managed. If a repair exceeds roughly 40–50% of the cost of a comparable replacement, consider upgrading, especially if you’ve faced multiple failures in a short window. Watch for rising fuel bills at the same thermostat settings; declining efficiency can be subtle until it hits your wallet. Also consider parts availability—if a crucial component is backordered or discontinued, downtime and future risk grow.

Replacement can introduce advantages beyond reliability: higher efficiency, quieter operation, better modulation, and smarter controls that temper short-cycling. However, an honest assessment may show your existing boiler still has solid years left with targeted repairs and improved water treatment. Prepare for any service or quote by gathering: the model and input ratings from the nameplate, a list of symptoms with dates, photos of the piping and venting, and notes about when issues occur (start-up, mid-cycle, shutdown). The clearer your information, the quicker a technician can zero in on root causes. Conclusion: with attentive maintenance and timely decisions, you’ll keep heat steady, safety uncompromised, and costs predictable, whether you repair today or plan a well-timed upgrade tomorrow.